Suraci has one of the largest capacities for coating rails, gates and fencing with over hundreds of miles of completed projects in the field our systems and processes have been successfully tested.

Abrasive blast cleaning done in house with no long wait times between blast cleaning and primer.

DOT Approved or Certified: CT, MA, RI,NY, & NJ. If you need a project done for a state project or DOT please allow us to become certified or approved with our experience, history and processes; its usually just a few days to complete.

- Specializing in Certified SureKote™Systems

- Paint, Powder Coating or Mix Process

- AESS standards

- Flouropolymers Coatings Systems

- Gates and Entrance Ways

- Hand Rails

- Pipe Rails

- Fencing & Guard Rails

- Small projects to Large ones

Having such large coating lines for both liquid or powder coating processes allows you to fabricate your assemblies in larger sections. Less field welds and less touchup means less cost.

Our Architectural line can handle a section of fence up to 50' long and 10 feet tall. Our batch can accommodate a 65' x 12' x 14' assembly whether its a stair assembly or small pedestrian bridge section we can powder coat or paint to your specifications.

On your smaller assemblies we have the option to coat them on several different lines with all of them capable of both Powder or Wet Coatings. Utilizing long cure ovens and multiple stage cleaning systems that apply chemical pretreatments, and rust inhibitors. All our lines have both manual or robotic coating systems on them, that means we can handle both small runs or large runs in short lead times while still delivering the highest of quality.

Featured completed projects:

3000 feet of hand rails and vomitory rails for Lucas Oil Felid Home of the Indianapolis Colts.

- Process: Surekote 6™; abrasive blast SSPC-SP10, zinc primer, then finish coat in a PPG polyester finish.

Schubert Theater Rails: This projects was challenging with having to abrasive blast the steel railing while not damaging the stainless handrails that were attached. This three coat process delivered in only a few days 800 feet of railings.

Above you can see the detail of the stainless steel hand rail attaché to a steel frame coated to a Surekote 6™

To the Right Hartford wire safety fencing abrasive blasted then two coats of powder Surekote 6™ Zinc Primer followed by a polyester finish coat.

Above Cabelas Stores Hand rails and decorative animal shape: abrasive blasted then two coats of powder Surekote 6™ Zinc Primer followed by a polyester finish coat.

Above Yankee Stadium Project Entrance ways: Metalized Steel, abrasive blasted SSPC-SP7, then coated in an epoxy primer follow by a fluoropolymer finish coat

Custom hand rails to commercially produced railings we supply all size projects.

Miscellaneous rails, stairs, fencing of all size projects.

Below Spiral Stair case systems Powder coated in a White Gloss Urethane finish after it was abrasive blasted and since primed.

AESS finished stair case rail system completed while assembled to their stringers.

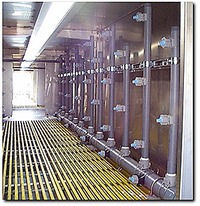

Below is a four coat CT DOT project for fencing coating in a liquid four coat process: Abrasive blasted SSPC-SP10, Zinc Primer, Epoxy intermediate Primer, Urethane coat and finished with a Urethane clear coat. over 1400 feet done on our automatic line. Here you see our hand spray operators applying the zinc primer, the next two coats was coated using a automatic electrostatic painting system. Then the final coat was done by hand.

Below is a large radius balcony rail fabricated in one pieces and then coated in a Surekote 10™ Zinc Primer, then a coat of epoxy primer, followed by a polyester finish coat.

Below is a fully assembled stair case system that was first hot dipped Galvanized before we allpied our Surekote-Galv 6™ SD system; abrasive blast SSPC-SP7, Epoxy Primer followed by a Super Durable polyester finish coat.

Below is a fully assembled section of a stair case system that was finished to meet an AESS specification, which required SSPC-SP10 blasted surface, girding, sanding, and filling work was applied to all seems and welds before an epoxy primer was applied. Once cured we reinspected all surfaces and sanded them to a smooth automotive quality finish. Then a second coat of epoxy primer was applied.

Below are fence section, which were coated in our Surekote FP 10™ Fluoropolymer Systems. The steel fencing was abrasive blast SSPC-SP10, Zinc Primer, then Epoxy Primer followed by a Fluoropolymer finish coat.